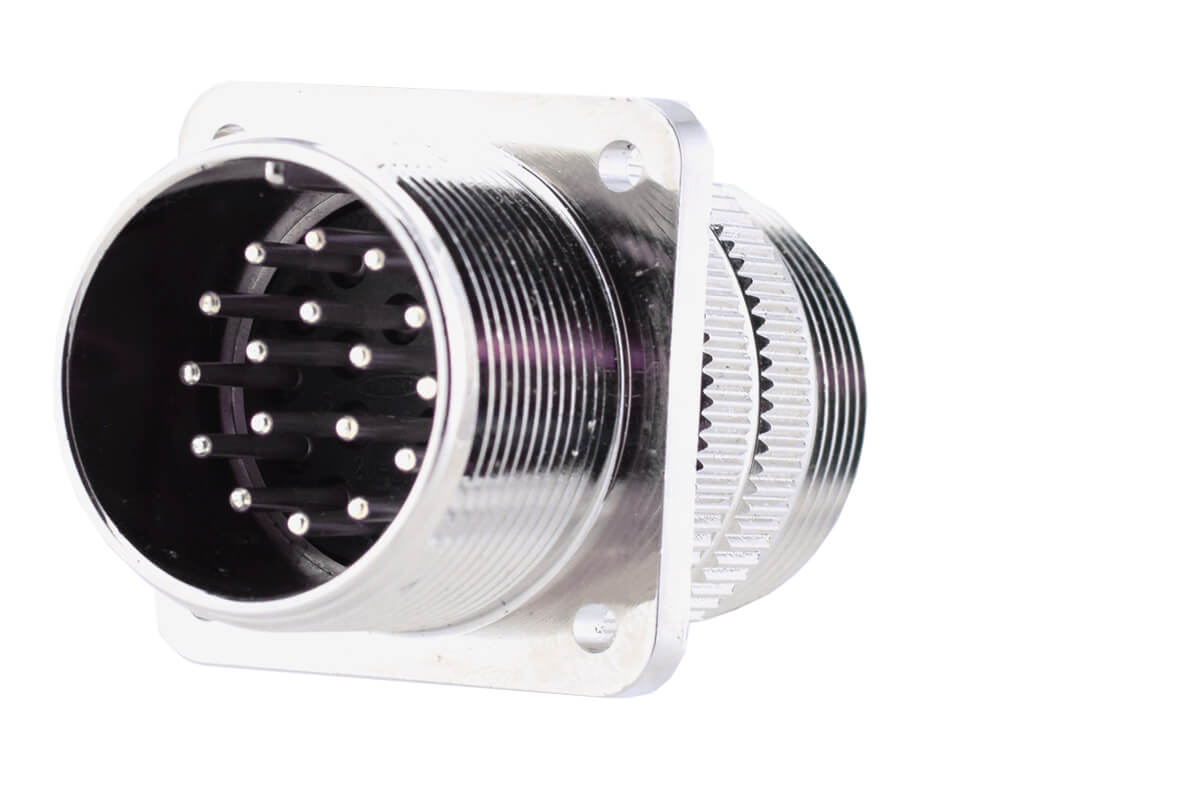

Environmentally-resistant, Amerline's AEC 5015 series connectors are general-duty, circular multi-pin connectors designed for harsh conditions. This style of connector meets the military specification for the connection of electrical systems and electronic devices in military and commercial aircraft. Currently, AEC 5015 series connectors are used in a wide range of industrial applications as well as military applications where commercial off-the-shelf (COTS) connectors can be used.

AEC 5015 Commercial Connector Series

AEC 5015 Products

AEC 3100

Wall Mounting Receptacle

AEC 3101

Cable Connecting Plug

AEC 3102

Box Mounting Receptacle

AEC 3106

Straight Plug

AEC 3108

90° Angle Plug

AEC 3057-A

Cable Clamp with Rubber Bushing

AEC 25042

Protective Cap for Plugs

AEC 25043

Protective Cap for Receptacles

AEC 5015 Commercial Series

-

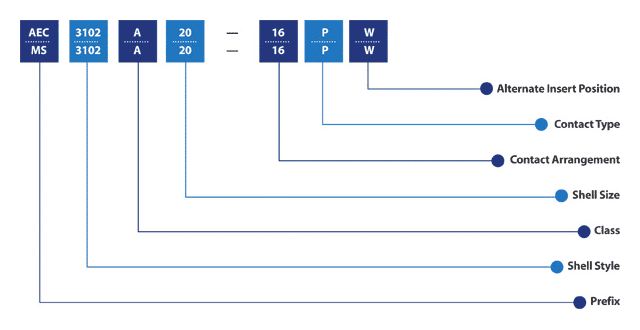

Part Number Explanation

Part Number Explanation

Prefix Contact Type Alternate Insert Position AEC (Amerline Enterprises Co.) P = Pin/Male contacts Blank (Normal) MS (Military Standard) S = Socket/Female contacts W, X, Y, Z -

Class

Class

Class Description A Solid Shell. Solder contacts & non-pressurized B Split Shell. Solder contacts & non-pressurized E / F Environmental with resilient insulators and integral cable clamp R Environmental with resilient insulators and shortened light-weight endbell : also additional sealing with O-ring seal under coupling nut in shell style 3106 and 3108 -

AEC 5015 Part Number Cross Reference

AEC 5015 Part Number Cross Reference

MIL Spec. Amerline MS3100 AEC3100 MS3101 AEC3101 MS3102 AEC3102 MS3106 AEC3106 MS3108 AEC3108 -

Characteristics

Characteristics

Insulating Resistance 5,000㏁ Min (at 25℃) Operating Temperature -55℃ to 125℃ Durability 500 Cycle Connection/Disconnection -

Environmental Test Data

Environmental Test Data

Operating Temperature -55℃ ~ +125℃ Vibration MIL-STD-1344 Method 2005 / 10 ~ 500㎐ (10G) Shock 50G / Time:11±1μs / Test current: 100㎃ Salt Spray MIL-STD-1344 Method 1001 / Salt solution: 5%/48Hours Humidity Relative Humidity: 95% ±3% / Temperature: 71℃ ±2℃ / 14 Days -

Material / Finish

Material / Finish

Shell Aluminum alloy, olive drab chromate coating over cadmium or zinc plating Insulator Synthetic rubber Contacts Copper alloy, Silver Plated -

Composition

Composition

-

Finish options

Finish options

Suffix Finish RoHS Blank Olive Drab over Zinc (default) BLK Black Zinc BR Electro-deposited Black (RoHS)

(500hrs salt spray test)

BZR Black Zinc RoHS

(Black trivalent chromate over zinc plating)

EN Electroless Nickel

N Nickel

OR Electro-deposited Olive Drab (RoHS)

(500hrs salt spray test)

-

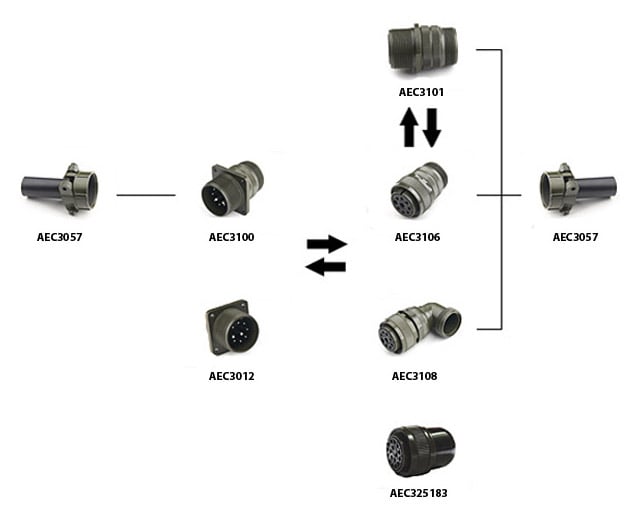

Shell Style

Shell Style

Style Description lass AEC3100 Wall mounting receptacle A, E/F, R AEC3101 Cable connecting plug A, E/F, R AEC3102 Box mounting receptacle A, B, E/R AEC3106 Straight plug A, B, E/F, R AEC3108 90° angle plug A, B, E/F, R AEC25183 Potting seal plug -

Alternative Insert Positions

Alternative Insert Positions

-

Contact Arrangements

Contact Arrangements

6 Most Frequently Asked Questions About AEC 5015 Series Connectors

What is a 3100 shell style designate?

A 3100 shell style is a wall mounting receptacle. A wall mount is a standard receptacle with a flange for front or rear mounting through a panel or bulkhead and includes accessory threads to accept a backshell.

What is the test current in (Amps) for a contact size 16?

The current rating at 68 degrees F (+20C) is 13 Amps.

What are the materials and finishes available for Series 5015 shells and endbells?

The shell and endbell material is aluminum alloy. The insulator, gasket and grommet are produced from synthetic rubber. The contacts are copper alloy with silver plating. Shell and endbell plating options are Olive Drab over Zinc, Black Zinc, Electro-deposited Black (RoHS) (meets 500hrs salt spray test), Black trivalent chromate over zinc plating, Electroless Nickel, Nickel, and Electro-deposited Olive Drab (RoHS) (meets 500hrs salt spray test).

What is the mating durability of the AEC 5015 connectors?

The durability is 100 cycles of mating / unmating operations to MIL-DTL-5015, 3.16.

What does the “OR” finish mean?

“OR” designates our Electro-deposited Olive Drab (RoHS) 500-hour salt spray test.

What is the vibration rating for the AEC 5015 series of connectors?

The vibration rating has been tested to 10 to 2000 Hz (10G units) 10 microseconds maximum discontinuity to MIL-STD-1344 Method 2005 condition II per MIL-DTL-5015.