Amerline's AEC 26482 commercial series of connectors are general-purpose, miniature circular connectors that are environmentally resistant. These styles of connectors are qualified for use in industrial and business applications with a bayonet coupling for rapid positive mating and unmating of the connector.

AEC 26482

Commercial Series

AEC 26482 Products

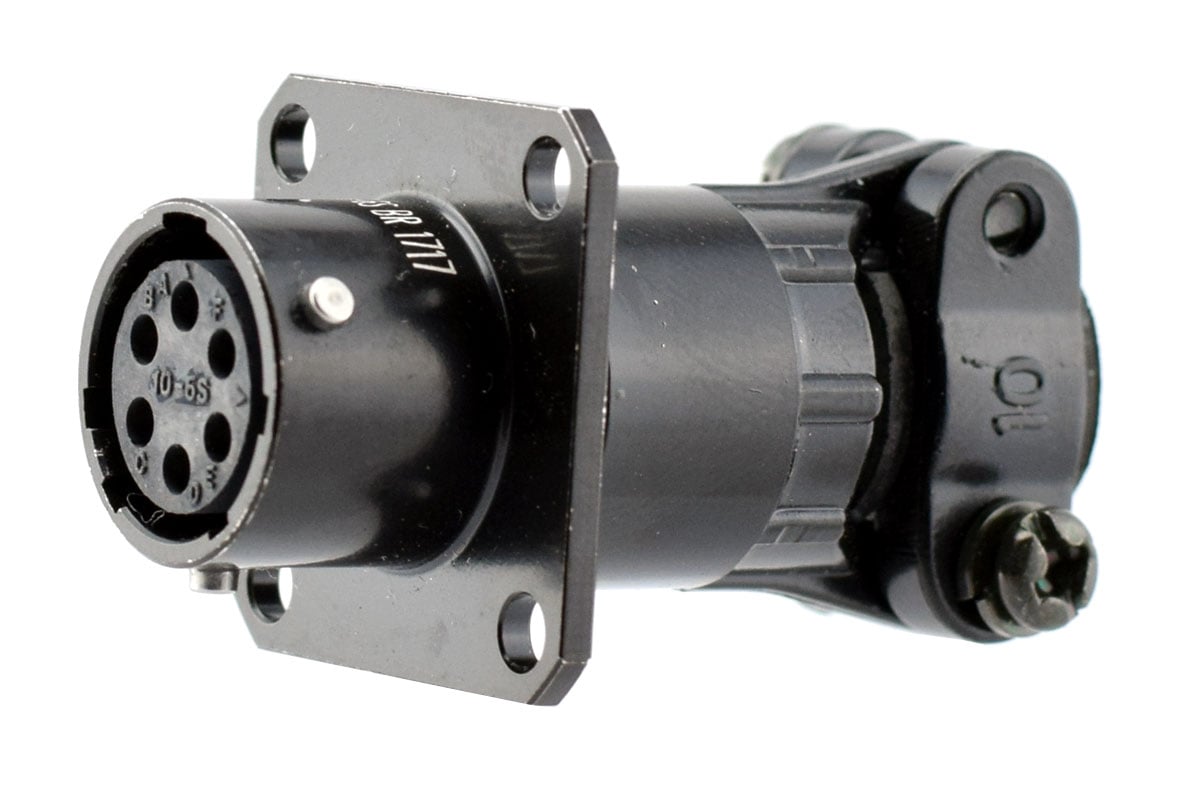

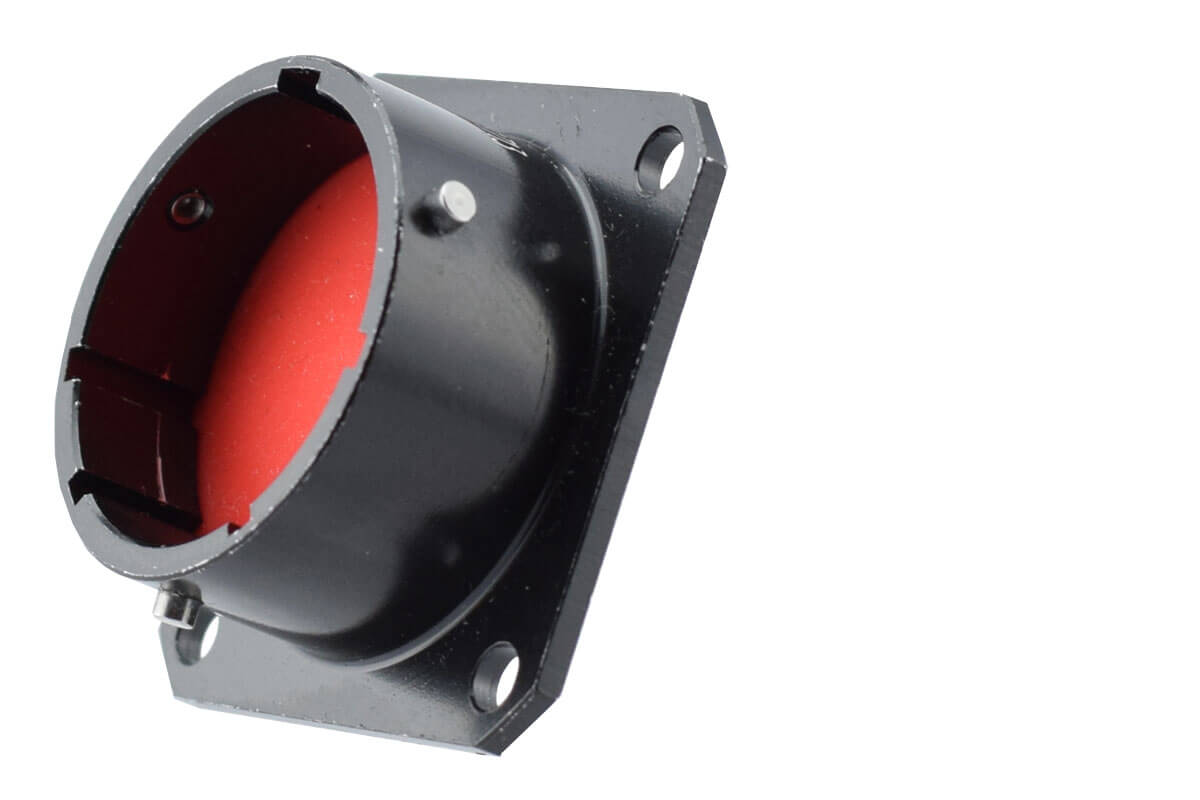

AEC 3110

Wall Mounting Receptacle

AEC 3111

Cable Connecting Plug

AEC 3112

Box Mounting Receptacle

AEC 3114

Jam Nut Receptacle

AEC 3116

Straight Plug

AEC 3115

Dummy Receptacle

AEC 3180

Protective Cap for Plugs

AEC 3181

Protective Cap for Receptacles

7 Most Frequently Asked Questions About AEC 26482 Series Connectors

What is the 26482 Series I connector?

AEC 26482 is a miniature, circular connector with quick disconnect bayonet coupling. It is widely used on applications requiring a general-purpose, miniature cylindrical bayonet connector.

What are typical applications for 26482 Series I connectors?

The AEC 26482 series connectors are used in automation, sensors, measuring equipment, aerospace applications, defense and transportation sectors.

What are the environmental ratings for the 26482 Series connectors?

AEC 26482 series connectors have an operating temperature range of -67 F (-55C) to +257F (+125C). The vibration resistance is 10 to 2000Hz (15g) 10 microseconds maximum discontinuity. Salt spray rating is 48 hours at environmental temperature (Cadmium Olive Drab) and 500 hours at environmental temperature (Electro-deposited Olive Drab / Black RoHS plating).

What are the advantages of using AEC 26482 Series I connectors over other connector types?

AEC 26482 Series connectors are highly reliable, quality interconnect solutions. They transmit higher signal rates, wider bandwidth and connectivity in a small footprint. They have a proven reliability, ruggedness and compatibility with military standards.

What is the difference between 26482 Series I and Series II?

Series I connectors offer solder contacts, are scoop proof and have bayonet coupling. Series 2 connectors offer removable crimp contacts and are intermateable with the equivalent series I connectors.

Are AEC 26482 Series I connectors available in different shell sizes and contact arrangements?

There are a variety of options available for AEC 26482 Series I connectors. When purchased from Amerline, they can even be customized to suit specific application requirements. Available from shell size 8 to size 24, there are multiple insert arrangements and alternate positions to select from.

Where can I purchase AEC 26482 Series I connectors, and what are the typical lead times?

AEC 26482 connectors may be purchased directly from Amerline or from any of our authorized distributors. Standard lead times are 16-18 weeks but may be expedited to 3-4 weeks.

AEC 26482 Commercial Series

-

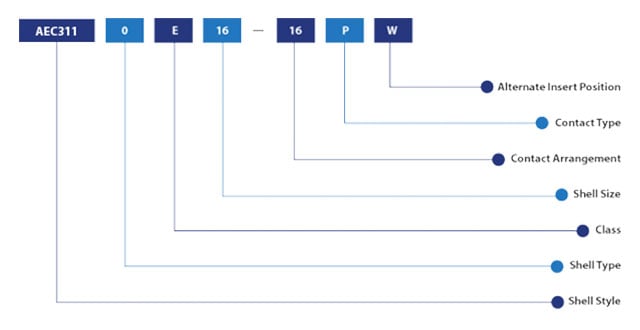

Part Number Explanation

Part Number Explanation

-

Shell Style

Shell Style

0 – Wall mounting receptacle 4 – Jam nut receptacle 1 – Cable connecting plug 6 – Straight plug 2 – Box mounting receptacle Thru-bulkhead receptacle -

Class

Class

A General duty F Grommet seal with strain relief E Grommet seal J Water tight gland seal with strain relief for jacketed Cable P Potting -

AEC 26482 Part Number Cross Reference

AEC 26482 Part Number Cross Reference

MIL Spec. Amerline MS3111 AEC3111 MS3112 AEC3112 MS3114 AEC3114 MS3116 AEC3116 MS3119 AEC3119 -

Electrical Data

Electrical Data

Service Rating MAX. Operating Voltage

(AC/DC)Testing Voltage (VAC. rms) Sea Level 50K

feet70K

feetI 600/850 1500 500 375 II 1000/1275 2300 750 500 -

Material / Finish

Material / Finish

Shell, Coupling Nut Aluminum alloy, olive drab chromate coating over zinc plating Insulator, Grommet Synthetic rubber Contacts Copper alloy with gold plating -

Current Rating

Current Rating

Contact Size Current Rating Potential Drop MAX. (mV) #20 7.5 AWG #20 ~ #24 #16 13.0 AWG #16 ~ #22 #12 23.0 AWG #12~ #14 -

Finish Options

Finish Options

Suffix Finish RoHS Blank Olive Drab over Zinc (default) BLK Black Zinc BR Electro-deposited Black (RoHS)

(500hrs salt spray test)

BZR Black Zinc RoHS

(Black trivalent chromate over zinc plating)

EN Electroless Nickel

N Nickel

OR Electro-deposited Olive Drab (RoHS)

(500hrs salt spray test)

ODZ Olive Drab over Zinc -

Alternative Insert Positions

Alternative Insert Positions

-

Contact Arrangements

Contact Arrangements